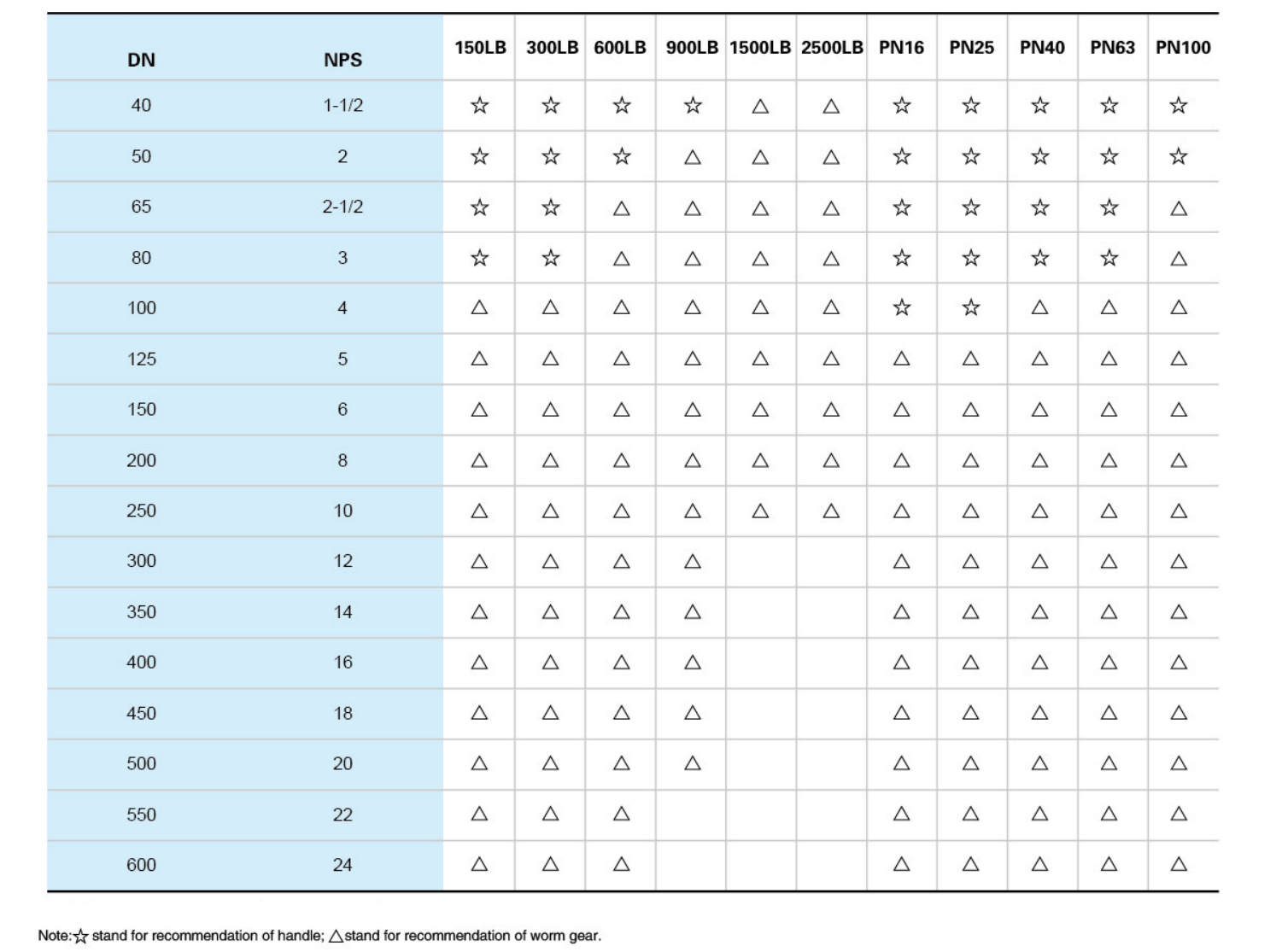

| Availability: | |

|---|---|

METAL-SEALED BALL VALVE ![]()

Overview of Metal-sealed Ball Valve

The ball valve has the characteristics of smal fluid resistance, smooth fow channel, quick opening and closing, and easy automatic control, so it has been more and more widely used. However, because the valve seat of the conventional ball valve is generally made of non-metallic materials such as PTFE, limited by the valve seat sealing material, the conventional ball valve can not be used under high temperature conditions, nor can it be used in solid particles, ash and other media, so the use of the conventional ball valve is limited to a certain extent. To this end, after years of efforts, Accton has successfully developed a full series of hard sealed ball valve products includina foatina ball valve and fixed ball valve,and has been widely used in coal chemical industry, polysilicon, petroleum, chemical industry, metallurgy, light industry and other industries.

Metal-seated ball valves are suitable for Class150-Class2500,PN16-PN160,JIS10K-JlS20K in various pipelines,used to cut off or connect pipelines.Ball valves made of different materials can be suitable for non corrosive medium, weakly corrosive medium,nitric acid,acetic acid,oxidizing medium,urea,and other multiple medium,especially suitable for harsh working conditions containing solid partides,slurny,coal powder,ash,and other medium.The operation of metal seated ball valve can be manual, worm gear, pneumatic or electric.Metal-seated ball valves are generally connected by flanges,and can also be butt welded,socket welded,threaded,and wafer connected.

![]() Design Features

Design Features

High temperature resistance,wear res,stance and corros1on resistance can be obtained by hardening the sealing surface.According to the different working conditions. A variety of hardening treatment methods are available.

1.

HVOF supersonic spraying:we and CrC hardened coatings were obtained on the sealing surface of valve parts using theHVOF process.The application temperature of WC hardening coating can reach 540°C,while Crc hardening coating canbe suitable for working conditions between 540° C and 950° C.This hardening process can achieve h 刃 h hardness,hightemperature resistance,wear resistance.impact resistance.and othe r characteristics.The hardness can reach58-BOHRC,and the thickness of the hardening layer is 0.2-0.25mm.

2.

Hard-facing,such as Stellite,can achieve a surface hardness of 38-45HRC and a hardened layer thickness greater than 1.6mm.

3.

Spray welding,spray welding nickel base alloy,cemented carbide, this way is similar to HVOF.spray welding metal powder on the sealing surface to obtain hardening coating.The hardness can reach SO -60HRc and the thickness of hardenedlayer is 0.8-1.5mm.

TRUNNION MOUNTED ![]()

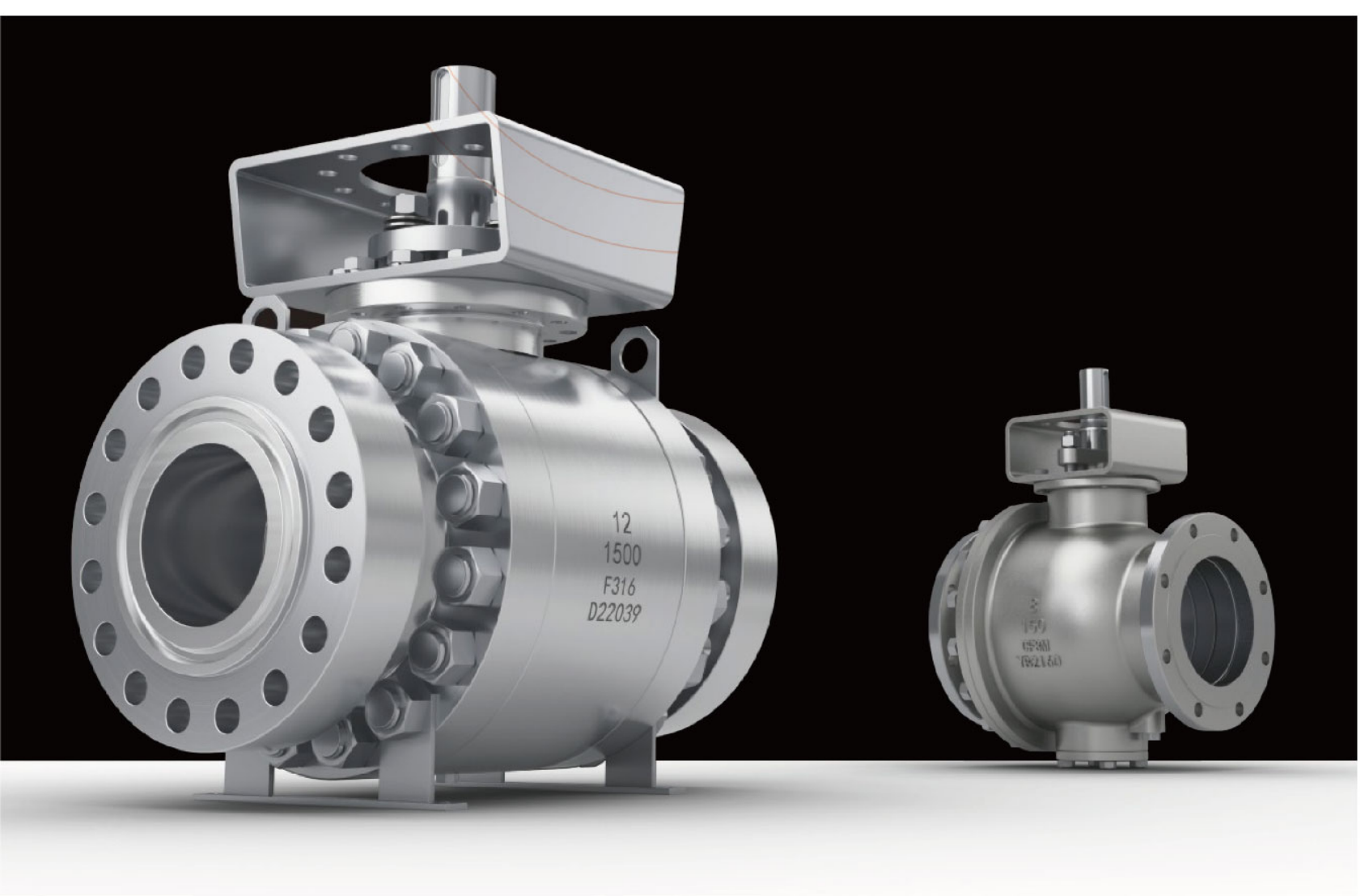

![]() Overview of Trunnion Mounted Ball Valve

Overview of Trunnion Mounted Ball Valve

Accton metal-sealed trunnion mounted ball valve is suitable for severe working conditions,such as high temperature, high pressure,strong corrosionand medium containing particles.Under working conditions,its seal is safe and reliable,with long service life,convenient operation and small pressure loss.

Due to the above advantages of metal-seated ball valve,the application of it is becoming increasingly widespread and receiving more and more attention from users and valve manufacturers

Optional Operation

![]() Design Features

Design Features